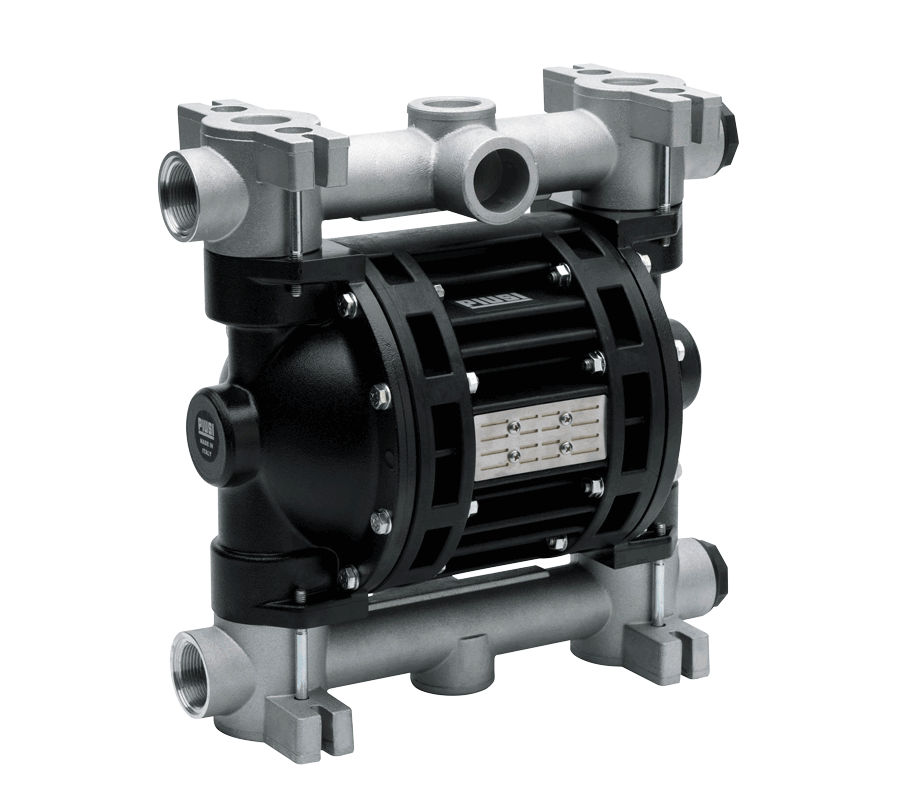

Diaphragm Pumps

5 stars based on

45 reviews

The diaphragms are not rigidly fixed to the shaft. Flexible Diaphragm Suspension reduces fatigue on the diaphragms, contributing to extend their service life.

Also, shaft life is significantly increased, since the diaphragm only pushes the shaft but does not transmit non-axial loads. This contributes to minimize pulsations, increases time between services and enables a central flow. The FDS principle is complemented with the use of short stroke diaphragms that reciprocate very quickly. Shortening the stroke length dramatically reduces the fatigue wear of the diaphragms and so extends their life.

A traditional sliding air valve could not be used as the friction in these kind of air valves is too high to allow the fast reversing action required.

The FPV is the heart of the reciprocate drive system and ensures very high operational reliability. The air distribution system including the directional air valve module, the end of stroke sensor valves, and the air channels is self-cleaning and withstands non lubricated, oily, dry, humid and dirty compressed air.

Pump maintenance has never been so easy. The entire pump can be disassembled without dismounting the fluid pipe lines. This makes atex certified air driven liquid pumps diaphragms, cleaning valves and other maintenance jobs easier and atex certified air driven liquid pumps than in other diaphragm pumps.

Online Catalogue Featured products. The reduced number of internal components results in a very reliable pump, with minimal maintenance requirements. Thanks to its central flow design, with no manifolds, the pump can be fully serviced without the need to disconnect the atex certified air driven liquid pumps distribution line.

Furthermore, routine service and maintenance air valve service, cleaning or replacing ball valves, replacing worn diaphragms, etc. Pulp and paper General chemical industry Concrete additives Surface treatment and finishing Detergent and soaps Waste treatment Metal works.

Discharge fluids at up-to 7 bar, to pump medium viscosity fluids even over long pipe runs and up to significant heights. No rotating shaft seals: No rotating parts and no tight clearances: Gentle pumping action suitable for shear sensitive fluids or fluids that may form emulsions.

Compressed air operation with no electricity required, inherently safe concept for environments with explosion risks. ATEX certified models available. Variable flow rate and pressure through simple adjustment of the atex certified air driven liquid pumps pressure. Superior performance against back pressure, less loss of nominal flow capacity under real application conditions.

Significant dry suction lift, eliminate self-priming issues pumping from drums and even tall tanks. Dependable atex certified air driven liquid pumps free directional pivot air valve: Tolerant of oil, moisture and dirt.

No air leaks when pumps are stalled by closing the fluid discharge line. Reduced air consumption per liter pumped, saves energy and possibly avoids the need to buy a bigger compressor. Reduced pulsation, greater accuracy during dosing and less splashing when dispensing. Lower vibrations and lower noise level. Inline servicing of air valve, diaphragms and ball valves, without disconnecting the plumbing. The low part count design allows fast and reliable servicing by non-expert technicians.