Current info for people in pahoa hawaii 96778 who want bitcoin process

36 comments

Kelebihan robot forex bitcoin trading bots impact factors

During bluetooth communication there is usually a short lag between each command transmission. This lag can be expected to not exceed 30ms at most, as stated in the official Mindstorms protocol documentation. From time to time however a significantly higher lag can be observed.

A packet will then be delayed up to 10 seconds this behaviour has only been verified when using Windows. The causes for this are likely to originate in the bluetooth stack or protocol itself and have yet to be closer examined. They seem to depend on the bluetooth signal strength, the used adapter model, the battery power of the robot and the system specification of the host computer.

When such a packet loss happens, the robot cannot be controlled during this time, e. That is why you should try to specify a certain tacho limit for the motor using NXTMotor. That way the motor will automatically stop at the correct position, even if the delay happens at the wrong time. Fact is that we are experiencing a timeout period whose length can be adjusted.

The default setting is 2 seconds, which reduces this period to a tolerable length. You can experiment with lower values, however do they have a drawback: Too short timeout periouds might cause real packet loss, meaning that data will actually be lost because the bluetooth stack cannot retransmit the lost data in time. This usually results in error messages or strange warnings "trying to collect a packet that was not requested".

Best performance depends on many factors, and the effects are unfortunately not always reproducable. See also section "Tutorial: The NXT light sensor measures brightness, actively or passively. Unfortunately, the detected intensity depends on the wavelength of the light and is not a linear function. Commonly spoken, warm light like sunlight or that produced by light bulbs results in a higher intensity, whereas cold light such as from neon lamps or white-blue LEDs only gets detected with lower intensity.

Hence a common problem is that daylight cannot be compensated by artifical light in such a way, that repeated measurements always yield the same values. So how do we cope with this? If a robot should be able to work in all scenarios with different illumination, there are mainly two possibilities:.

Either the program requests a reference each time it is started, i. This is basically a calibration process, that might even be supported by future NXT firmware versions an according datafield is already reserved.

The other way is to take the surrounding light into account: Measure the daylight or artificial light of the environment. This brightness can then be used to calculate the real brightness using the value obtained from the sensor. Maybe the easiest way is to make sure the robot always operates in similar illuminated situations.

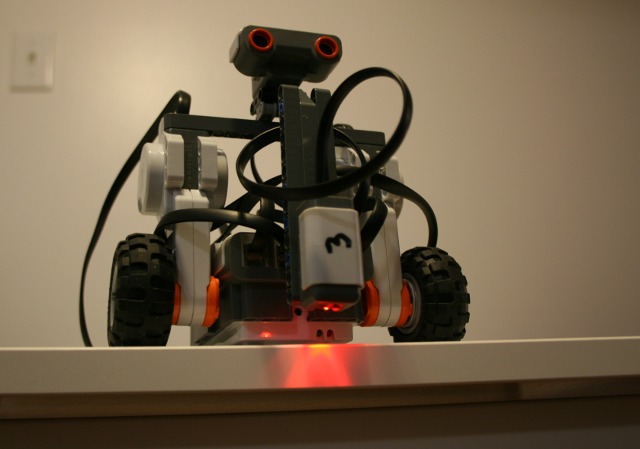

Please note that multiple ultrasonic sensors in one room or on one NXT could influence each other. First of all you need surfaces that reflect ultrasound. Not suitable are usually things with very soft surfaces, especially cloth or fur-like structures. One of the most important things to consider is the angle the sensor is facing towards the object: Round surfaces, just like bottles, are extremly difficult to outline accurately.

They reflect the ultrasonic impulses in too many directions, hence you get echos of imaginary objects that are not really there. The spreading of the ultrasonic sensor is very wide anyway: It is probably best to stick to flat, hard, big objects at first. This section does not apply when using the NXTMotor class! The NXT motors have a certain way they always try to reach the most accurate position. This may lead to some unexpected effects. It only happens when using a certain rotation limit specified by TachoLimit.

Imagine you want to rotate a motor degrees. As you set a relatively high power, and a certain rotational moment is involved, the motor will turn further than its set angle limit.

Basically at the exact position of , the power will be turned off, leaving the motor spinning in coast mode until it comes to a stop. Let us just imagine this would be at degrees. The motor now "remembers" that is has just turned degrees too much.

The next time, when you issue another "rotate by " command, what do you expect? The motor keeps an internal memory of cumulative commands containing angle limits. This means, when you send the second "move " command, the internal sum is now at This is the new target to be reached.

In this case it does not matter that you start at already. The motor "realizes" that there are only degrees missing until To put it another way, if the motor is off by degrees one time, it will try to correct it the next time. This results in periodic movements that are "too far" or "too short", depending on what you send, and what you expect. Do not turn any motors by hand while the NXT is still turned on, unless you know exactly what you are doing. If the internal counters do not get reset properly, the NXT motor will try to "correct" these changes you made by hand the next time it receives a command containing an angle limit.

For driving robots, the regulation mode "synchronization" is very handy to drive straight lines or curves parameters SyncToMotor and TurnRatio of DirectMotorCommand. When sending multiple commands to synced motors, e. It has been found that these problems can be fixed by calling the following functions inbetween the different track sections:. For better performance especially when using USB connections on slow machines , it is recommended to run this toolbox function:.

For more details, see help section "Optimizing Performance". It can also help when you want to trace certain conditions leading to errors, or when you're experiencing timeout problems. To enable debug messages inside the command window, just type:.

The complexer the functions get, the longer those error messages will be. Most of the time, they are the best clue you have in order to find out what went wrong. It can be a bit confusing when all those red words take up lots of space inside your command window, or when errors repeatedly occur again and again.

Note that your command history will not be touched by this. The last results from your command window will be cleared however. It can be amazing how clean an error message suddenly looks when starting the program again in an empty command window