Liquid ring vacuum pump function

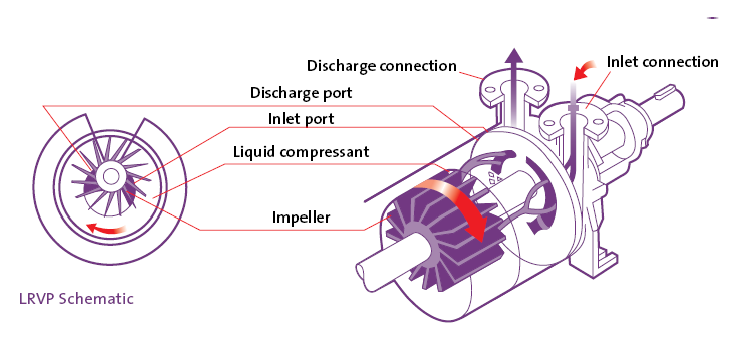

This liquid can be water, oil or any other solvent which is rotated by an impeller within the casing of the pump. The vacuum pumps that use water as sealant are called water ring vacuum pumps. When rotated this liquid forms air seals within the spaces between the impeller vanes which forms compression chambers that trap the air entering into pump frequently through the inlet port.

This process repeats and therefore helps in creation of vacuum. Unlike other pumps, which are used for only vacuum creation and pumping operations, a liquid ring vacuum pump can be used as a gas compressor as well. It can compress gas with its impeller rotating mechanism and is therefore a useful device for several applications.

The vacuum pumps based on liquid ring technology are employed in several industries including paper, sugar, power, petrochemical, seawater deaeration, pharmaceutical, fertilizer, asbestos, oil refineries, distilleries, railways, textile, food, mineral etc. The best applications usually handled by these pumps include vacuum distillation, vacuum condensation, moisture extraction, ash or air handling, mineral beneficiation, evaporation jobs and liquid ring vacuum pump for removing water from paper pulp during paper processing.

The liquid ring pumps offer number of advantages over the other pumps and therefore are preferred in various applications. These pumps can easily take care of condensable vapors and can even handle fluids of various kinds without affecting the performance of the pump. Based on liquid ring technology, pumps have only one rotating or prime functioning part and therefore are economical and much easier to maintain than the other pumps.

Single-stage vacuum pumps typically produce vacuum to 35 Torr mm Hg or 47 millibars 4. Some ring-liquid is also entrained with the discharge stream. This liquid is separated from the gas stream by other equipment external to the pump. In some systems, the discharged ring-liquid is cooled by a heat exchanger or cooling tower , then returned to the pump casing. In some recirculating systems, contaminants from the gas become trapped in the ring-liquid, depending on system configuration.

These contaminants become concentrated as the liquid continues to recirculate, eventually causes damage and reduced life to the pump. In this case, filtration systems are required to ensure that contamination is kept to acceptable levels. In non-recirculating systems, the discharged hot liquid usually water is treated as a waste stream. In this case fresh cool water is used to make up the loss. Environmental considerations are making such "once-through" systems increasingly rare.

These simple, but highly reliable pumps have a variety of industrial applications. They are used to maintain condenser vacuum on large steam-turbine generator sets by removing incondensable gasses, where vacuum levels are typically 30—50 mbar. They are used on paper machines to dewater the pulp slurry and to extract water from press felts.

Another application is the vacuum forming of molded paper-pulp products egg cartons and other packaging. Other applications include soil remediation, where contaminated ground water is drawn from wells by vacuum. In petroleum refining, vacuum distillation also makes use of liquid-ring vacuum pumps to provide the process vacuum.

Liquid-ring compressors are often used in vapor recovery systems. Liquid-ring vacuum pumps can use any liquid compatible with the process, provided it has the appropriate vapor pressure properties, as the sealant liquid. Although the most common sealant is water, almost any liquid can be used. The second most common is oil. Since oil has a very low vapor pressure, oil-sealed liquid-ring vacuum pumps are typically air-cooled. For dry chlorine gas applications concentrated sulfuric acid is used.

The ability to use any liquid allows the liquid-ring vacuum pump to be ideally suited for solvent vapor recovery. If a process, such as distillation or a vacuum dryer, is generating toluene vapors, for example, then it is possible to use toluene as the sealant, provided the cooling water is cold enough to keep the vapor pressure of the sealant liquid low enough to pull the desired vacuum.

Ionic liquids in liquid-ring vacuum pumps can lower the vacuum pressure from about 70 mbar to below 1 mbar. From Wikipedia, the free encyclopedia. Ionic liquids — designable materials for high-performing fluids. Retrieved from " https: