Yahoo bot maker 2011 makerbot replicator 2

For the last couple years, a MakerBot press release has generally signaled that more pink slips were going to be heading out to the already shell-shocked employees at their NYC factory.

All the buzz words are there, at least. Sharing knowledge and listening to the community is essential if you want to connect with hackers yahoo bot maker 2011 makerbot replicator 2 makers. The spectacular fall from grace that MakerBot has experienced, from industry leader to afterthought, makes this hat-in-hand peace offering hard to take seriously. But to summarize quickly, the highlights go something like this:.

They also produced hardware that not only had rampant vendor lock in, but also planned obsolescence. They really have nobody to blame but themselves for their constantly shrinking market share.

MakerBot is proud to announce the arrival of MakerBot Labs, an experimental platform for engineers and developers to create, yahoo bot maker 2011 makerbot replicator 2, customize, and collaborate on MakerBot 3D printing solutions. Manufacturers like UltimakerLulzBotPrintrBotand of course Prusa Research all manage to deliver printers that not only make use of the collected knowledge of the open source community, but actively give back.

So what exactly is MakerBot Labs? Think about it, really let it settle in. It is a rectangle. With a smaller rectangle subtracted from the center. This is after they already encased their yahoo bot maker 2011 makerbot replicator 2 in a plastic box to begin with.

So now you have a plastic box to hold your plastic box. Interestingly enough, back in Makerbot used to sell yahoo bot maker 2011 makerbot replicator 2 whole selection of different sized nozzles for their early 3D printers ; no lab coat required.

Cooper impersonation in The wheels of progress turn slowly in any yahoo bot maker 2011 makerbot replicator 2 organization, and perhaps doubly so in one that has gone through so much turmoil in a relatively short amount of time.

Is there still a road back into the hearts and minds of makers for MakerBot after all these years? Open source printers are offering features like multi-material extrusion, high flow hotends, automatic leveling, and filament out sensors, while MakerBot counters by offering a 3D printed block to store your overpriced extruder in. Jabs at MakerBot aside, of course we would all like to see them return to the open source principles that put them on the map.

It would serve as a cautionary tale for other manufacturers; a practical case study in how the open source community can make, and in time perhaps even break, a tech startup. To be sure, Labs is not the fundamental shift that we would like to see out of MakerBot. With any luck, MakerBot will treat Labs not as a destination, but a path forward. What do you think?

With no shortage of hackable printers on the market, what would it take to get a MakerBot back into your lab? I was yahoo bot maker 2011 makerbot replicator 2 of this. Check out my live printing with it: I wish I bought 2 instead on the crappy Prusa i3 clone. How about they take those things they patented extruders, continuous bed, etc and release them as open sourcefor starters?

It really tells what Open Source is about. I recommend it to anyone that wants to know what Open Source is about. I had to watch it twice but not twice in a row just because it was so good. And it also helps that XYZprinting replies are so entertaining although very much wrong. I had debated mentioning the responses he got from XYZprinting, especially since they were really so similar to what MB is saying in their Labs announcement.

But I thought it prudent to only call out one manufacturer a time. Seriously these companies need to get it through their heads that once you screw over a community you will never get it back. I worked for Local Motors for a little white and they basically did the same thing, build up a community that supports you, then crash it into the ground an alienate everyone. BTW, makerbot yahoo bot maker 2011 makerbot replicator 2 off commenting on there latest youtube posts. Do a filter search for the yahoo bot maker 2011 makerbot replicator 2 month.

Lulzbot is doing it right — STLs for every part, every line of code, everything is on their website. I bought their printer because It is really well designed and reliable. Now I buy their filament because I want to support the company. I thought they already did. Why would one even deal with them for one second when prusa exists? Yahoo bot maker 2011 makerbot replicator 2 has been left in the dust and is structurally too wrong to ever make it back in.

Bre screwed it up and he can go play in the yahoo bot maker 2011 makerbot replicator 2 now. Why did Stratasys buy Makerbot in the first place? They had already ran their name down into the mud.

Surely Stratasys already had the manufacturing resources to put out a decent little consumer-grade desktop printer. They could have made up some new name to sell their consumer grade stuff.

I would have thought that burning their money to heat their factory would have been a better use than buying out Makerbot! Probably to remove a competitor from the market, since Makerbot had a name.

I bet they never really wanted their business anyway, but got tired of customers asking why they should pay a 3D printer a few thousand dollars when they could buy one of these cheaper printers instead.

And why remove them as a competitor? They were a dying, nearly dead competitor at a time when new, lively competitors were coming into their yahoo bot maker 2011 makerbot replicator 2. How much better did the market look to them after competition from Makerbot was removed?

By that logic perhaps Comcast should consider buying AOL or maybe Prodigy or Compuserve because it would eliminate a competitor. They tried to buy a customer base, then move them upmarket, away from DIY into spendy more profitable closed boxes… kinda like how BMW bought Mini and turned it into a generic douche mobile clone and pissed off all classic mini fans.

They had already pissed all their customers off and sent them into the arms of their newer competitors. They wanted to buy themselves into this new market of cheap printers. As their machines started at 50k with service contracts, they had no clue on how to enter this market quickly, so they bought the market leader. The real answer is always in the comments.

Something like one of those cable printers we saw last week. The community is still trying to pull the knife that makerbot put there from their backs…. No way they will get a second chance there, they have burned that bridge to the ground.

Too bad Colorfabb seems to be jumping on their bandwagon. Why do programmers get Halloween and Christmas mixed up? Tom, Thanks for a well written and thoughtful article, some very good stuff here. Keep up the good work and hopefully you can get an article together with the info from the Local Motors commenter above.

Their only hope is to do something dramatic. Dramatically change their values, their prices and leadership. The infrastructure is there, the brand identity is arguably ok to newbies.

This article is inside baseball news directed at engaged makers… whom I love, btw. But consumer 3d printers dont exist yet so when they do some big yahoo bot maker 2011 makerbot replicator 2 w rcoeriencecand deep pockets stands a good chance. In short, they need a new leader, a new vision and to divorce from the company they are tied to… Apple did it and dominated.

But they had the beloved leader w the vision willing to make bold moves. And they had the timing, luck and the love of people wanting to be a part of a Cinderella story. Makerbot has none of that. It may be over. Being CEO also means having to balance whats new and cool with budget realities.

I never regretted canceling the full-color printer project after watching Markerbot misrepresent the current technology to disappointed consumers. The only way that this company will survive is to open source every last part of the machine. No proprietary hardware, weird chips, and lack of debugging interfaces that are easy to access except to those of us with 36 AWG wire and a microscope.

If someone manufactured a 3-D printer as stable as a laptop computer, then even a closed-source one would be acceptable to much of the public. However they make it hard for you to fix them. If I have to use some special extruder that will break in a new way and require me to buy a replacement, then I may as well buy something with a less interesting extruder make from hardware store parts.

If Makerbot wants to overcome its bad name from its mistreatment of its customer base, then it has to make the most reliable printer ever. Which laptop computer did you have in mind?

The HPs that desolder their own yahoo bot maker 2011 makerbot replicator 2 chips, or the Powerbooks with swelling batteries? The Makerbot is quite fast, and you can monitor the build from your office.

We finally have place a high end printer on order and plan a metal printer next year. I hated when they got bought out, the sad thing being that their products DID work great, and they are generally reliable. Wow, really good article. My channel saleslady is trying to convince us that the new plus machines really are better than the 5th Gens. I offered to pay shipping so we could test drive one for a couple weeks, she never took us up on that or even acknowledged it.

I own a MakerBot Replicator Mini and I have had quite a few problems keeping it going including three extruder replacements. MakerBot is very hard to communicate with when there product fails. Seems nobody knows enough to diagnose it over the phone and then charge me dollars for an extruder.

It was acquired by Stratasys in June As of AprilMakerBot has sold overdesktop 3D printers worldwide. Smith was one of the founding members of the RepRap Research Foundation, [7] a non-profit group created to help advance early research in the area of open-source 3D printers. The company started shipping kits in April and had sold approximately 3, units as of March Demand for the kits was so great in that the company solicited MakerBot owners to provide parts for future devices from their own MakerBots.

In AprilZachary Smith was pushed out, [14] involving disagreement on adherence to open source principles, and likely also about integration with Stratasys. Yahoo bot maker 2011 makerbot replicator 2 security led out employees laid off around the same time.

The deal provided that MakerBot would operate as a distinct brand and subsidiary of Stratasys, serving the consumer and desktop market segments.

When acquired, Makerbot had sold printers. In Aprilit was reported that in an effort to integrate MakerBot's activities better with those of Stratasys, Jaglom laid off around of employees and closed the existing three MakerBot retail locations. MakerBot's first products were sold as do it yourself kits, requiring only minor soldering, with an assembly process compared to assembling IKEA furniture. The source files needed to build the devices were put on Thingiverseallowing anyone to make one from scratch.

Because of the open source nature of the product, any suggestions for improvements came from users. During its primary production run April to Septemberthe Cupcake CNC kit was updated several times to incorporate new upgrades into each successive version.

It shipped with many of the aftermarket upgrades that had been built for Cupcake. The stock Thing-O-Matic included a heated, automated build platform, an MK5 plastruder, a redesigned z-stage and upgraded electronics. The Thing-O-Matic was discontinued in the spring of Assembly instructions are available online through the MakerBot Wiki. As such, the Thing-O-Matic can be heavily altered and improved by users. Some MakerBot operators developed upgrades to the platform that were later incorporated into factory kits.

MakerBot has credited those early innovators in their documentation, [25] and even on some of the PCB silkscreen layouts. In January MakerBot introduced the Replicator. It offered more than double the build volume of the Thing-o-Matic at Other features included a dual extruder allowing two-color builds, an LCD screen and a control pad. The Replicator was sold pre-assembled with no kit version available. It was the last open-source MakerBot printer.

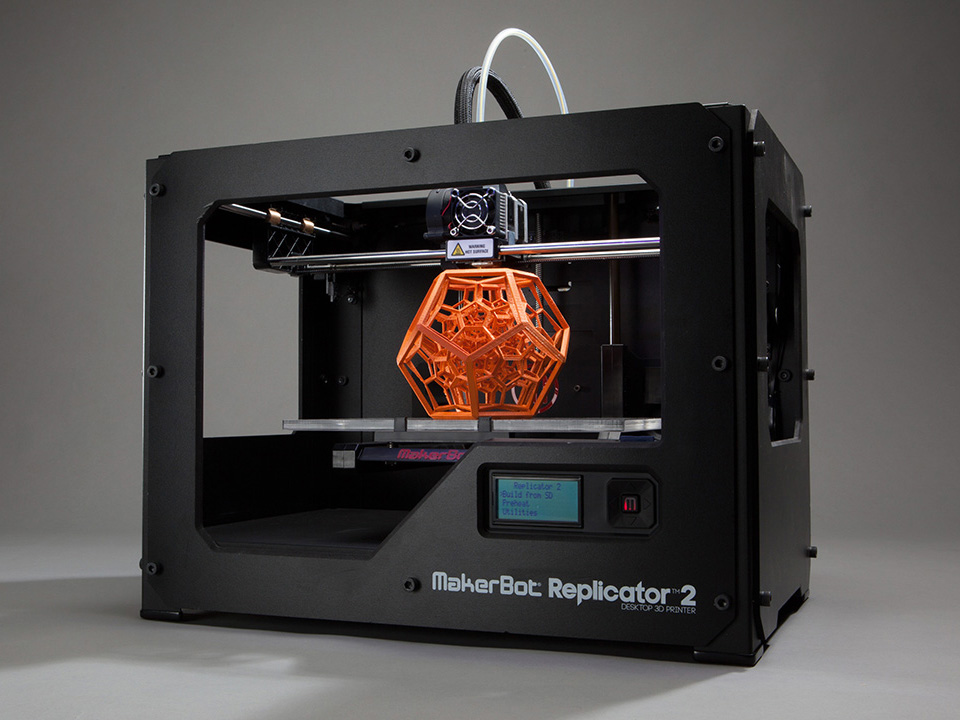

In SeptemberMakerBot introduced the Replicator 2. This newest model yahoo bot maker 2011 makerbot replicator 2 increased the build volume, this time to The dual extruder was changed back to a single extruder head, while the upgraded electronics, LCD, and gamepad remained similar to the original Replicator. Unlike previous models, the Replicator 2 can print only using PLA plastic, which comes sold in sealed bags with desiccate to protect it from moisture. The 2X model was intended as an experimental version of the 2 yahoo bot maker 2011 makerbot replicator 2 includes a completely enclosed build area, redesigned dual-extruders, and a heated aluminum build platform — all of which enable printing with ABS plastic and dual-material printing.

The product was designed to allow MakerBot users to scan physical objects and turn them into digital, 3D printable models. The accompanying software allowed models to be edited, printed immediately, or uploaded to Thingiverse.

Released alongside the Replicator Mini and 5th Generation Replicator, the Z18 offers a build volume of Envisioned as a solution for major clients, the MakerBot Innovation Center incorporates hardware optimized suite of 3D PrintersSAAS workflow software, [32] training services, and enterprise support.

Until midmanufacturing was performed in its own facilities in New York, then it was contracted to Jabil Circuit. The New York manufacturing personnel was laid off, while development, logistics, and repair operations remain in New York. MakerBot hosts the online community Thingiversewhere users can upload 3D printable files, document designs, and collaborate 3D printing projects and on open source hardware. The site is a collaborative repository for design files used in 3D printing, laser cutting and other DIY manufacturing processes.

They sent a bust of Stephen Colbertprinted on a MakerBot 3D printer, into the stratosphere attached to a helium filled yahoo bot maker 2011 makerbot replicator 2 balloon. Netflix published in September the documentary Print the Legend about Makerbot history. Yahoo bot maker 2011 makerbot replicator 2 to its detachment from open source community, the departure of its founders, reliability problems with the 'smart extruder' and questionable users clauses on the Thingiverse site, [41] there have been many recent controversies [42] around Makerbot.

Additionally, the company has lost substantial market-share to competitors such as Ultimaker and Aleph Objects. The Fifth generation was equipped with an interchangeable extruder with some self-diagnostics capabilities. It was new in the market and supposed to help printer maintenance but reliability problem occurred with very short lifespan on the extruder, requiring frequent replacement at high cost. This led to a class action lawsuit [47] which was dismissed [48] [49] Ultimately, Makerbot replaced the failing extruder with a new version.

Around September the company stated that for their new Replicator 2 they "will not share the way the physical machine is designed or our GUI". With these models, MakerBot transitioned yahoo bot maker 2011 makerbot replicator 2 open source hardware controllers, extruders, and firmware to proprietary versions of the above. They also changed print file formats from the S3G format used by earlier printers to the new STL format.

Inthe company faced significant criticism when it filed patent applications for designs that some claimed had been invented by members of its yahoo bot maker 2011 makerbot replicator 2 and published to Thingiverse, such as yahoo bot maker 2011 makerbot replicator 2 quick release extruder. Community members accused MakerBot of asserting ownership over their designs when those designs had been contributed with the understanding that they would remain open source.

Then-CEO Bre Pettis released a statement dismissing these critics, citing patents that had been filed for unique inventions prior to any community-created designs, namely that the patent for the quick release extruder was originally filed in while the open source design was first published to Thingiverse in From Wikipedia, the free encyclopedia.

Get paid to make parts for future MakerBots. Retrieved August 24, Open Source — A Founder Perspective". Retrieved June 19, Advances in Autonomous Mini Robots: Retrieved 2 February Retrieved 30 November Archived from the original on The 3D Hubs Trend Report launches every quarter, using data from 6, active service providers creating 1, 3D printed parts. Retrieved from " https: Companies based in Brooklyn Yahoo bot maker 2011 makerbot replicator 2 established in Computing output devices Manufacturing companies based in New York City 3D printer companies establishments in New York state 3D printers 3D scanners Fused filament fabrication Startups companies.

All articles with unsourced statements Articles with unsourced statements from April Official website different yahoo bot maker 2011 makerbot replicator 2 Wikidata and Wikipedia Coordinates not on Wikidata Articles containing video clips. Views Read Edit View history.

In other projects Wikimedia Commons. This page was last edited on 19 Aprilat By using this site, you agree to the Terms of Use and Privacy Policy. Wikimedia Commons has media related to MakerBot.