Liquid ring pump efficiency chart

The gas capacity changes to after a polytropic expansion process and then enters the next operating cycle: Operation at any elevation above sea level will decrease the pump horsepower but also decrease the motor rating and the thermal horsepower rating of the gearbox. The theoretical result considerably deviates from the actual performance due to the lack of the fundamental study on the performance and restricts the improvement of performance liquid ring pump efficiency chart reliability of liquid ring pump. With the revolution of the impeller, the operating liquid is ejected outwards due to centrifugal forces and forms a liquid ring.

By referring to the formula of disk friction power in centrifugal pump [ 20 ], liquid ring pump efficiency chart equation 12 of liquid friction loss can be corrected as Therefore, the shaft power of liquid ring pump is written as The global efficiency is finally estimated by the following expression [ 13 ]: The operating principle of the liquid ring pump is illustrated in Figure 1. Comparisons of curves between the test and theoretical model. Therefore, it is of significant scientific and application values to carry out the fundamental study on the operating theory and performance of the liquid ring pump. Priming Valves Nash priming valves were designed specifically for Nash vacuum pump priming systems.

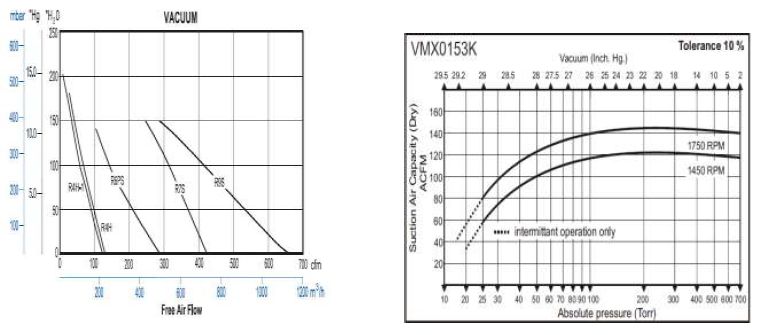

Finally, read from the power curve the power needed at this operating point. Liquid ring pump is a kind of rotary liquid ring pump efficiency chart machines, including liquid ring vacuum pump and liquid ring compressor. Operation at any elevation above sea level will decrease the pump horsepower but also decrease the motor rating and the thermal horsepower rating of the gearbox.

Why oversize the drive? Although numerical approach plays an important role liquid ring pump efficiency chart understanding internal flow field of liquid ring pump, it is still hard for practical application, due to the restriction of detailed 3D geometry of liquid ring pump, consumption of computation time, and the accuracy of gas-liquid two-phase liquid ring pump efficiency chart model. As shown in Table 1the theoretical suction capacity, determined by the impeller rotational speed and the geometric parameters of liquid ring pump, remains constant regardless of the compression ratio of discharge pressure to suction pressure.

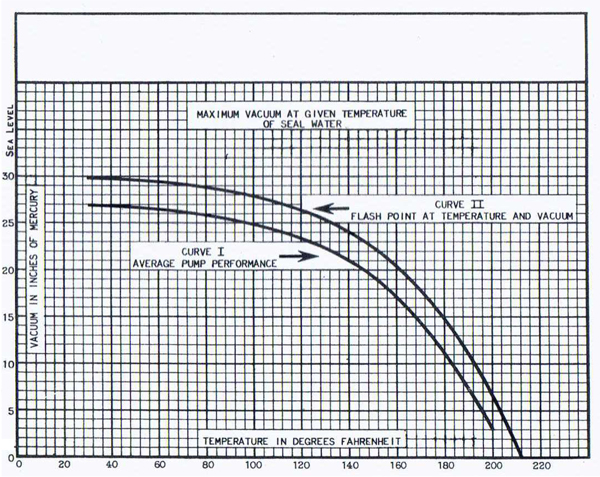

Like the actual operating principle of reciprocating compressor, however, some residual gas capacity is is still available in the liquid ring pump after gas discharge and returns to the suction zone; the residual gas changes to in capacity after a process of expansion Curves in Figure 2 b and goes to the next operating cycle. Constructed of L stainless steel, the series offers excellent liquid ring pump efficiency chart resistance and can be outfitted with a variety of mechanical seals. The actual suction capacity in a liquid ring pump is if. In general, higher seal water temperature will result in lower pump capacity and higher horsepower.

The expansion process is likely near the adiabatic one due to a shorter expansion time and path. This indicates that the expansion process of the residue gas is near the adiabatic one due to a shorter liquid ring pump efficiency chart time and path. Then, go to the curve and find the speed of the vacuum pump to achieve the flow that you want at the vacuum level desired.

Given the high cost of energy and the high cost of running a plant and the much higher cost of having the plant shut down, sizing of the drive becomes a compromise of capital cost, drive efficiency, factor of safety, and prediction of future vacuum needs. Therefore, it is of significant scientific and application values to carry out the fundamental study on the operating liquid ring pump efficiency chart and performance of the liquid ring pump. The actual suction capacity in a liquid ring pump is if .