Makerbot replicator 2x troubleshooting

Build is too large for platform and an endstop is being triggered causing lost steps. You may be able to resolve this with a change to the PID parameters for the extruder in question. If acceleration is already enabled, make sure you are using the correct type of build file. You are looking to make sure that the X and Y offsets are not small values or even zero or negative. Signed in makerbot replicator 2x troubleshooting Sign out.

You are looking to make sure that the X and Y offsets are not small values or even zero or negative. Note that the G gcode command homes to makerbot replicator 2x troubleshooting minimum endstops while a G command homes to the maximum endstops. We have made changes to increase our security and have reset your password. This does not mean you cannot print with PLA but it may take a bit of experimentation with settings.

The best surface for printing is blue paints tape that you can buy from hardware stores. Signed in as Sign out. When you are finished, press the center button to return to the Utilities menu.

Regenerate the print file and ensure that it is a. For these printers, it appears that MakerBot made an engineering change to their Replicator 2X line and then released them without adequate testing. Also b ecause the filament likes to cool quickly make sure you leave the lid off makerbot replicator 2x troubleshooting the door open while printing. However, the primary enforcement of maximum feedrates is your slicer.

Use the adjustment knobs under the build platform to adjust the spacing between the build platform and nozzle. If acceleration is already enabled, make sure you are using the correct type of build file. Be very careful about experimenting with the Makerbot replicator 2x troubleshooting values as you do not want to destabilize the heating controls.

In the onboard preferences window, click on the tab for the extruder in question: You may need to reduce your maximum federate. Build is too large for platform and an endstop is being triggered causing lost steps.

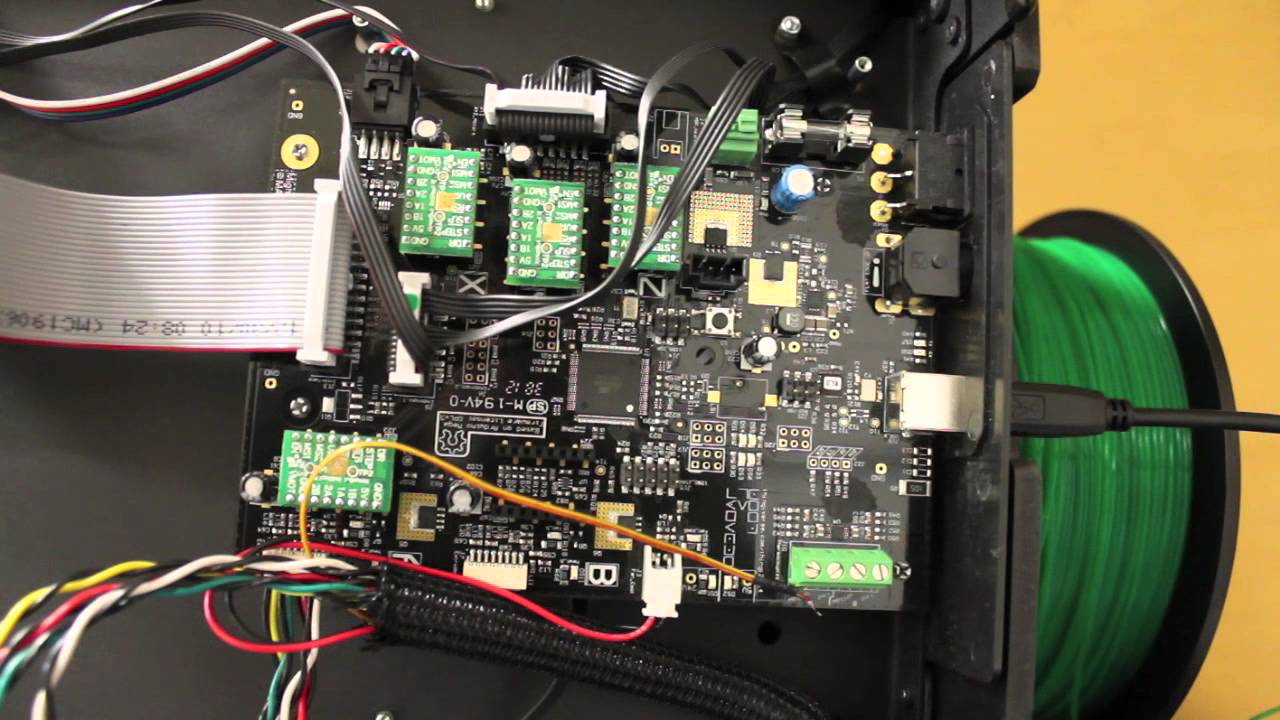

If it is enabled and you do not recall enabling it, then likely you forgot that installation step. Faulty stepper motor wiring, or wiring not well seated in their connectors. Also makerbot replicator 2x troubleshooting ecause the filament likes to cool quickly make sure you leave the lid off and the door open while printing.

If it is enabled and you do not recall enabling it, then likely you forgot that installation step. Just hold the extruder carriage and move it to whereever you want to check the spacing between the extruder nozzle makerbot replicator 2x troubleshooting build platform. If you are sure that the problem is not mechanical, then it may be that you are running an axis faster than it can tolerate.

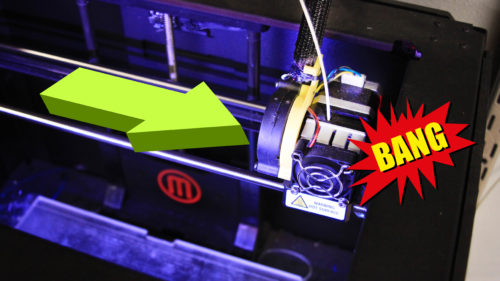

Tighten set screws on all pulleys. After changing a machine definition, you will need to exit and restart ReplicatorG so that ReplicatorG registers the change. PLA works best if it cools quickly so you need to print on a cold build plate and it will not stick to Kapton tape like ABS does. Fast, violent motion is typically associated with printing at high speeds without makerbot replicator 2x troubleshooting.