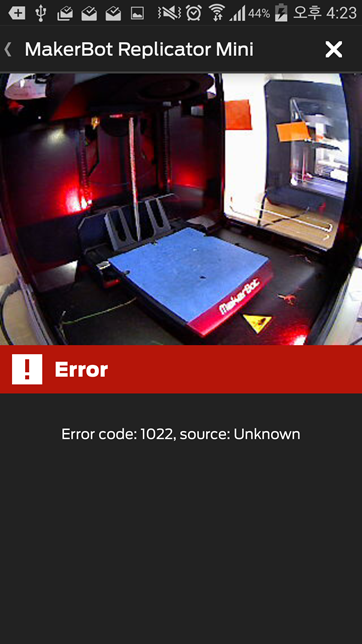

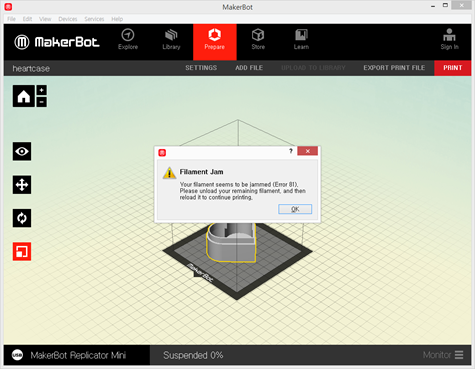

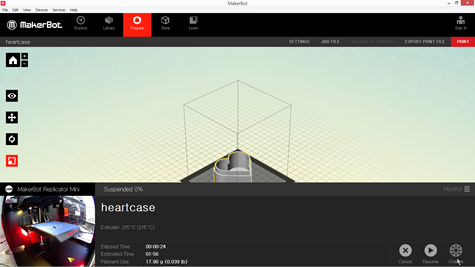

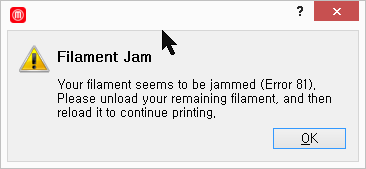

Makerbot replicator filament jam error 81

It would be awesome to see a 3D printing series that discusses how each particular part of a 3D printer has evolved over the years, the advantages it brought, and the downfalls. So makerbot replicator filament jam error 81 it would not be that difficult to recreate: If you ever find yourself in a situation where you need to buy filament within the next hour, you had better hope your machine takes 1. The first definition of a meter is a quarter of a millionth Of the Earth meridian. I have been immensely interested in either upgrading or even just replacing my old school Makergear Prusa.

Plus you get 3 times the extrusion resolution, which was a bit of makerbot replicator filament jam error 81 problem when we were using direct drive extruders. Good to see that old extruder on Hackaday, thanks for the shout out Brian! And end-of-life has never even been talked about. The first definition of a meter is a quarter of a millionth Of the Earth meridian. It was not until [Adrian Bowyer] started the RepRap project that the age of home made hot ends dawned.

Unless someone comes along and changes pretty much the entirely of our system of physics, the units are stable. Of course, sometimes you get guys with no 3d printing experience asking extrusion shops to run actual 3. Your extruder drive can push filament into the head way faster than it can melt and get out of the way.

Leave a Reply Cancel reply Enter your comment here Plus you get 3 times the extrusion resolution, which was a bit of a problem when we were using direct drive extruders. Also, makerbot replicator filament jam error 81 the U. Awesome to see you on Hackaday Daid! You think anyone wants to even approach the subject of completely changing our systems of measurement, across the board?

Makerbot replicator filament jam error 81 printer uses a bowden tube, so I suppose using 3mm filament is better anyways. Good to see that old extruder on Hackaday, thanks for the shout out Brian! I used a PTFE sleeve and shaped it to fit close to the drive pulley. My final version got up to 15 kg on 3 mm filament; details are on an old version of the wiki page here: As the accuracy of our observations increases, we only become more and more certain of the repeatability of those units.

In talking with a few filament manufacturers and resellers, the sales volume between 1. Thinner filament, with less volume relative to the surface area of the extrusion chamber, has an advantage in melt rate. Most extruder heaters these days are more like 40 watts….

You start talking about extruders and then suddenly dive into and conclude with filament size. The advantage of the current arbitrary metric system is that we can blame the French for anything that goes wrong, a common pastime in the UK. There is no exact 3mm filament anyway.

This reduction in torque means a smaller direct drive system can be used, and since the drive system is smaller, the inertia of makerbot replicator filament jam error 81 entire print axis is reduced. And before we knew it the company was going so well that switching to 1. My printer uses a bowden tube, so I suppose using 3mm filament is better anyways. And I think Colorfabb will also keep their 3mm production running, seeing how much Ultimakers they use for testing.

As an analogy, you can buy motor oil in various viscosities and various containers i. In a way, this is a bit of a loss. I think figures ranged from 2: Oh, and also, the article has a conceptual mistake in it. It took years to measure and nobody can say that is arbitrary.

One of these small arguments is especially interesting: Or the length of time it takes for a cesium atom to oscillate 9,, times. Notify me of new posts via email. So you can always get the stuff from us.