Bitcoin and cryptocurrency technologies a comprehensive introduction review

22 comments

Lego robot mindstorms nxt robotics kit 8547 cena

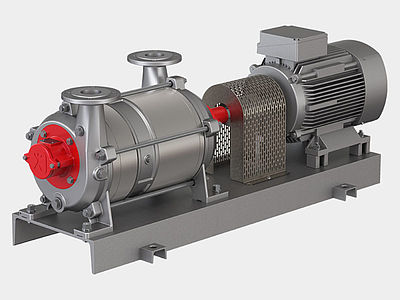

A rotary vane vacuum pump is an oil-sealed rotary displacement pump. The pumping system consists of a housing 1 , an eccentrically installed rotor 2 , vanes 3 that move radially under centrifugal and resilient forces and the inlet and outlet 4. The inlet valve, if available, is designed as a vacuum safety valve that is always open during operation.

The working chamber 5 is located inside the housing and is restricted by the stator, rotor and the vanes. The eccentrically installed rotor and vanes divide the working chamber into two separate compartments with variable volumes. As the rotor turns, gas flows into the enlarging suction chamber until it is sealed off by the second vane. The enclosed gas is then compressed until the outlet valve opens against atmospheric pressure. The outlet valve is oil-sealed. When the valve is open, a small amount of oil enters the suction chamber and not only lubricates it but also seals the vanes against the housing stator.

Operating principle of a rotary vane pump. In the case of gas ballast operation, a hole to the outside is opened, which empties into the sealed suction chamber on the front side.

As a result, the pressure needed to open the outlet valve is attained at relatively low compression during the compression pumping phase. The final pressure reached during operation with gas ballast is higher than in operation without gas ballast. Pump oil, which is also referred to as operating fluid, has multiple tasks to perform in a rotary vane pump.

It lubricates all moving parts, fills both the dead volume under the outlet valve as well as the narrow gap between the inlet and outlet. It compresses the gap between the vanes and the working chamber and additionally ensures an optimal temperature balance through heat transfer.

Rotary vane vacuum pumps are built in single- and two-stage versions. Two-stage pumps achieve lower ultimate pressures than single-stage pumps.

Moreover, the effects of the gas ballast on the ultimate pressure are lower, as the ballast gas is only admitted at the high pressure stage. Depending upon the type of pump in question, rotary vane vacuum pumps may be equipped with a vacuum safety valve. The vacuum safety valve isolates the pump from the vacuum chamber in the event of intentional or unintentional standstill, and uses the displaced gas to vent the pumping system in order to prevent oil from rising into the vacuum chamber.

After switching on the pump, it opens after a delay once the pressure in the pump has reached the approximate pressure in the vacuum chamber. Know How Vacuum generation Rotary vane vacuum pumps.