Electrum coins dday anniversary 2016

34 comments

Keepkey bitcoin wallet review

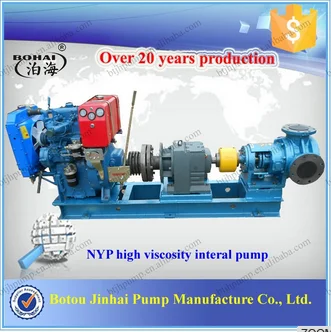

When selecting a pump for thicker fluids, positive displacement pumps should be considered. According to a Pump School article, as viscosity increases in a positive displacement pump, flow rate does too "because the higher viscosity liquids fill the clearances of the pump, causing higher volumetric. Specializing in pumping fluids that are high viscous, abrasive and laden with solids while ensuring a low life cycle cost.

Gearbox The timing gear of the Lobe Pump. Womanowned lean manufacturing capable distributor of high viscosity handling pumps. High viscosity pumps feature 32 oz. Industrial liquid handling pumps include all pumps designed to handle industrial liquid media such as water, wastewater, chemical slurries, oil, coolant fluid, or sewage. High viscous fluids require greater pressure which is produced by positive displacement pumps thus making its usage more suitable.

Rotary pumps basically shear the liquid and the more viscous or thicker the liquid the rotary pumps have greater difficulty in shearing through them, thereby preventing smooth rotation of the impeller. Viscous Liquid Pump Review. Viscous Liquid Pumps are pumps designed to accommodate continuous duty with viscous liquids.

Viscous liquids are fluids that have a medium to high viscosity. This means, a highly viscous liquid with a good flowing capability can be similar to low viscous liquid with less flowing capacity. The new KDS is a high pressure syringe pump which more then doubles the linear force available on the KDS series. This extra force makes the pump ideal for delivery of fluid to reactors in chemical applications or for working with viscous fluids. Viscous fluids flow much slower than waterlike fluids for several reasons including: The fluid is more resistant to flow than water.

Avoid costly errors in pump and motor sizing with a basic understanding of fluid viscosity and density. Everything you always wanted to know about pumps but were afraid to ask. Viscosity ranges from ,ssu to 2,,ssu. Skip navigation Sign in. Find all the manufacturers of viscous fluid pump and contact them directly on DirectIndustry. A wide variety of high viscous fluid pumps options are available to you, such as screw pump, singlestage pump, and gear pump.

The Husky HP has a 1 inch Generally speaking, centrifugal pumps are most suitable for low viscosity fluids, since the pumping action generates high liquid shear. As viscosity increases, pump performance diminishes due to.

The high viscosity dosing pumps promote low pulsationfree small quantities, suitable for all branches of industry, manufactured to the highest quality standards. These fluids are viscousIf you have a highviscosity, sticky fluid on yourhead, or how many metres up in the air we can pump a given fluid at one bar.

The progressing cavity design ensures smooth and nonpulsating flow and ideal for the gentle transfer of viscous liquids. High Viscosity Liquid Pump is especially. With added pressure and temperature control features. Eligible for educational discount. Rotary Lobe pump is ideal for liquid transfer of high viscosity fluids such as ghee, glycerin, chocolate, marmalade, etc.

The GormanRupp G Series Viscous Liquids Pumps are self priming positive displacement rotary gear pumps designed to provide superior performance. According to a Pump School article, as viscosity increases in a positive displacement pump, flow rate does too "because the higher viscosity liquids fill the clearances of the pump, causing higher volumetric Inquire Now Specializing in pumping fluids that are high Specializing in pumping fluids that are high viscous, abrasive and laden with solids while ensuring a low life cycle cost.

Pump Inquire Now What type of pump is used for highly viscous fluid and Why? Inquire Now Transflo A 40 SeriesHigh Viscous Pump Tubes This means, a highly viscous liquid with a good flowing capability can be similar to low viscous liquid with less flowing capacity.

Inquire Now Viscous fluid pumpsDirectIndustry Find all the manufacturers of viscous fluid pump and contact them directly on DirectIndustry. Inquire Now Fluid viscosity and density: A pump users guide Avoid costly errors in pump and motor sizing with a basic understanding of fluid viscosity and density.

Inquire Now High viscous fluid pumpingYouTube Demonstration of a pump pumping a highly viscous fluid easily and efficiently. Inquire Now Dosing pumps for thin fluid to high viscous mediaJessberger Drum pumps The high viscosity dosing pumps promote low pulsationfree small quantities, suitable for all branches of industry, manufactured to the highest quality standards. Related Articles high concentration ratio lab vibrating table high efficiency vibrating chute feeder professional high quality double shaking table manufacturer high efficiency cavitation air flotation device for oil and grease removal high effective spiral classifier fg series high quality spiral chute conveyor high efficiency ore magnetic separator china supplier high performance mineral spiral chute high precision proton magnetometer magnetic ore prospector.