Charles lee litecoin price

42 comments

Steam gift card bitcoin stock

You may also want to check out the previous assembly photos also featured on Slashdot. Pictures of the laborious assembly process went up several days after, and have been viewed by tens of thousands of people in the last few weeks alone. A good thing, indeed! Rough high-level steps are as follows:.

Within ReplicatorG, launch the embedded Skeinforge configuration application, which is used to take 3D design files in. This is necessary since 3D printers usually print in layers, starting with the lowest. Skeinforge is an extremely configurable system with an extremely shitty GUI.

Even after calibration, you will need to periodically revisit Skeinforge to address build-specific issues. ReplicatorG build platform positional and orientation. Use ReplicatorG to either upload a compiled. S3G files to the on-board SD card for disconnected printing, or stream the commands on the fly.

Run the test job! The workflow is initially very daunting and cumbersome. It starts to make more sense after a while, but needs major work. Documentation is 4 of 5. The 5 is for comprehensiveness and getting me through the process, but -1 for ocassionally erronous images, ambiguous text, or omission of step.

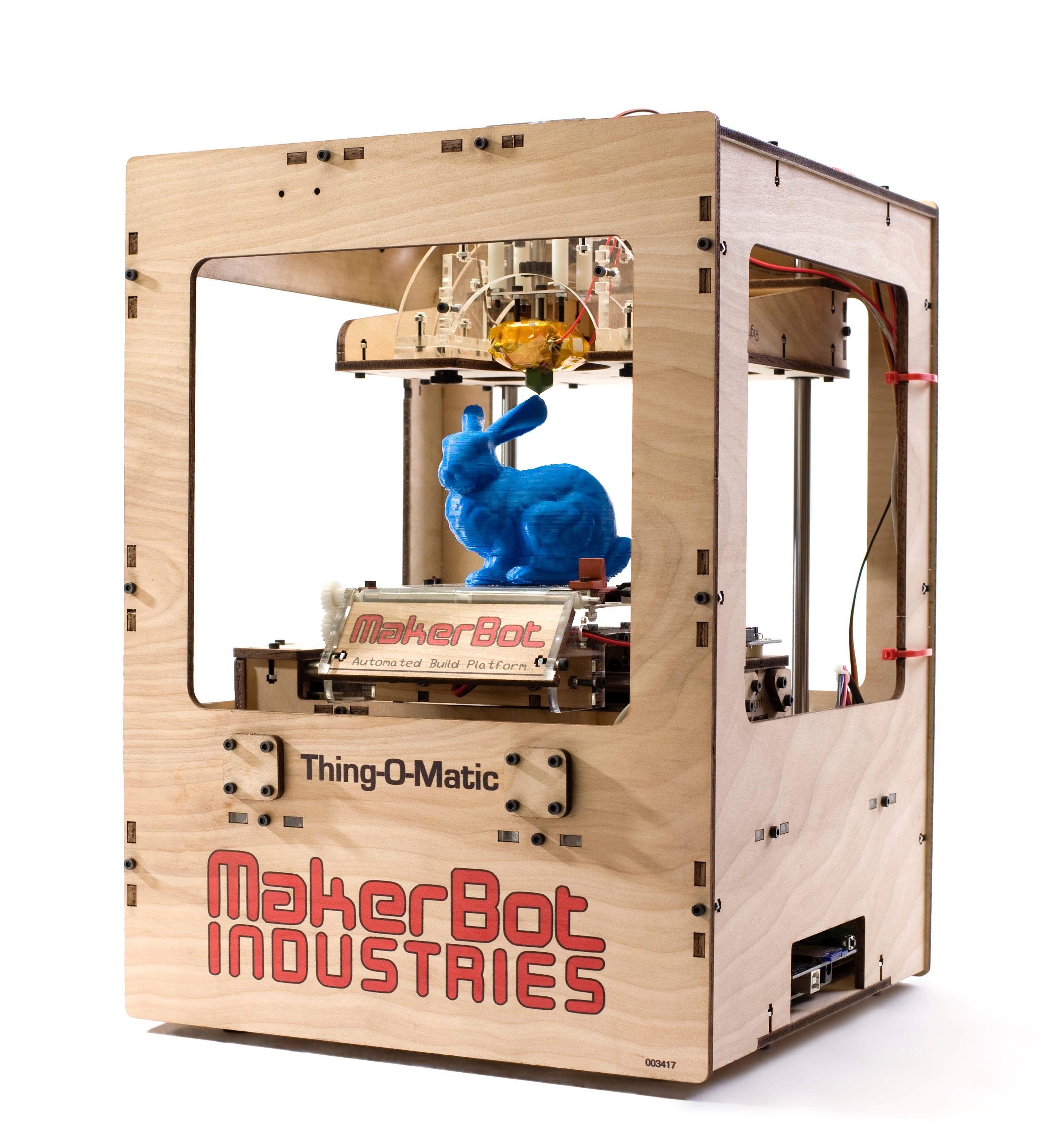

You can print many of your own replacement parts if some break. Many small pre-fab printer shops have materialized in the last couple years, ranging from laser-cut wood frames such as Makerbot , to clear acrylics, metals, and, of course, printed plastics. Regardless of your chosen path, the electronic components are currently not printable in any high-quality manner, are best purchased from a vendor.

This includes mainboard microcontroller the Thing-o-Matic uses as Arduino MEGA , stepper motor controllers, stepper motors, power supply, end stop sensors, extruder controller, cables etc. Makerbot is a good choice for U. If you want a RepRap, the choice is more difficult. With external powered USB devices incl. HDDs etc some people have even noticed sparks when connecting using improperly grounded outlets. The rapman is the closest you can get to a reprap darwin.

With well working software in a fraction of learning time, or even mill molds for plastic parts if you like. What do you think about the quality of the parts you can make? With a small amount of sanding and razor work they can actually come out looking pretty good, though you often have to make build-specific configuration tweaks. You can of course paint the parts as well, or even put on a narrower extruder nozzle. So yeah, there are major cons to working with plastics, but there are also significant pros.

The specific design need will dictate which works better for a specific application, and none will be perfect for every possible need. These drivers seem inherently flakey on OS X. It also happens with my FitBit base station, which uses a SiLabs driver…. Having an open connection by running ReplicatorG etc.

You note that only minimal soldiering is required. I suppose the soldiering is necessary when the makerbot starts self replicating and tries to take over the world, and am glad this is kept to a minimum. Thank you very much for your review, I think from what I see this is not the solution for my intentions.

Would you be able to print it for me and send it over to Montreal, Canada if I provide the. If so, let me know where to upload the file. Thank you for this post. How likely would I be to just wreck the thing, or to never get it working properly? Are the instructions sufficient for a newbie with patience to actually follow, or will it likely require a lot of reading between the lines, and experienced improvisation?

Much of the guide is fairly ho-hum busy work, though a part may give you grief, here and there. You can google it easily — but many have figured out their project instabilities due to these. Even google all the problems with the Cisco access points home ones the problems are sucky caps. I think the idea here is to prototype something without making a steel mold first.

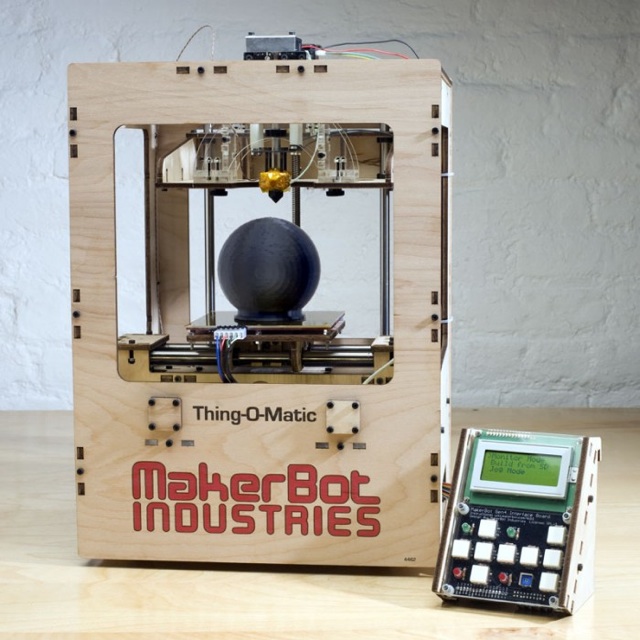

Thanks for the note. Hi Preston, I read your blog about the thing-o-matic and was very impressed with your knowleddge and reporting. Do you have any suggestions for what companies are experts at this, or what might be the best available options? I think the company should sell extrusion material at cost—just to promote the machine? Your email address will not be published. The Makerbot Thing-o-Matic, fully assembled and ready to print.

The Next Generation—which could recycle almost any object—the Thing-o-Matic and the like have already begun branching out from the 3mm ABS plastic spools used build the objects in the following pictures.

Unboxing of the Thing-o-Matic kit. See links for assembly pictures. My 3D model of an identical pair of custom solar cell brackets, done in Google SketchUp. Rough high-level steps are as follows: Install the Arduino driver , if not already installed. Easy Download and run ReplicatorG, and try making a software connection to the machine.

Use ReplicatorG to manually control all the machines widgets, and test each one for proper function. Load up some plastic filament. Skeinforge interaction can be a frustrating chore. Once many initial configuration jobs are complete, your time in software will generally be spent across two applications:. ReplicatorG and included Skeinforge application , tweaking, compiling, and babysitting. The Makerbot MK5 plastruder turns 3mm filament into hot, sticky plastic goo.

ABS is essentially Lego plastic, and solid at room temperature. Grab a handful of Lego bricks to get a feel for the weight, texture, color of ABS. At the melting point slightly above degrees Celcius, ABS turns into a half-solid, half-liquid ooze that is melty enough to extrude into the shape of your choice, while remaining solid enough to hold form long enough to cool back into a solid. Many different colors of ABS filament are available. And shipping is not free. Revisions 1, 2 and 3 of the solar cell bracket, from left to right.

Given the complexity of the machinery, you have a lot to consider before making the investment. You will almost definitely be the only kid on the block with this toy. Makerbot maintains the Thingiverse: Semi-automated batch jobs via the included Automated Build Platform. All needed parts and come with the kit. Supplies such as ABS are also available from Makerbot. Four solar cell bracket are shown partially assembled into a larger structure.

Generally not robust enough to run unattended. Something, somewhere, is dying a horrible death and taking my whole operating system with it. Skeinforge—the software that converts your 3D models to tool paths—has an absolutely atrocious and ofter unstable user interface. The machine can be somewhat loud and obvoxious. If you do this, you are making a very big time commitment. Questionable electronic sub-component failure rates, and one of my biggest complaints.

The motor on my MK5 Plastruder was dead on arrival, and my power supply went out after less than a dozen prints. I could just be unluckly, though. Lots of small custom components. Four iterations of the 20mm test cube: Competition is available, but thin and very fragmented.

Special thanks to Ethan H. You can also grab an older model at significant discount. Another 20mm test cube being printed. The biggest barrier to entry is not price, but difficulty. No fabrication, assembly, software, design, calibration, of troubleshooting process is theoretically undoable by any able-bodied person, but the same can be said for rocket science.

You need a decent understanding of robotics, hardware, software, electronics and mechanics, need a little hand dexterity and a ton of patience. Consumer 3D printing is still in its infancy, but the Makerbot Thing-o-Matic and ancestry are clear and decisive steps towards a day when all forms of matter can be assimilated from raw materials as easy as loading a coffee maker.

My power supply has an fatal failure after a handful of prints. Makerbot has sent a replacement free of charge. The blow-out seems to be a capacitor.