Coingecko ethereum prison

40 comments

Dogecoin reddit wolong reserves

Modified-release dosage is a mechanism that in contrast to immediate-release dosage delivers a drug with a delay after its administration delayed-release dosage or for a prolonged period of time extended-release [ER, XR, XL] dosage or to a specific target in the body targeted-release dosage.

Sustained-release dosage forms are dosage forms designed to release liberate a drug at a predetermined rate in order to maintain a constant drug concentration for a specific period of time with minimum side effects. This can be achieved through a variety of formulations, including liposomes and drug-polymer conjugates an example being hydrogels.

Sustained release's definition is more akin to a "controlled release" rather than "sustained". Extended-release dosage consists of sustained-release SR and controlled-release CR dosage. SR maintains drug release over a sustained period but not at a constant rate.

CR maintains drug release over a sustained period at a nearly constant rate. Sometimes these and other terms are treated as synonyms, but the United States Food and Drug Administration has in fact defined most of these as different concepts.

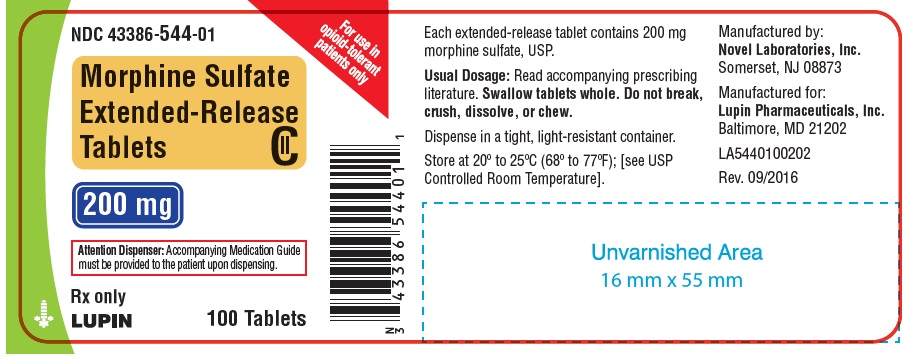

Modified-release dosage and its variants are mechanisms used in tablets pills and capsules to dissolve a drug over time in order to be released slower and steadier into the bloodstream while having the advantage of being taken at less frequent intervals than immediate-release IR formulations of the same drug. For example, extended-release morphine enables people with chronic pain to only take one or two tablets per day. Most commonly it refers to time dependent release in oral dose formulations.

Timed release has several distinct variants such as sustained release where prolonged release is intended, pulse release, delayed release e. A distinction of controlled release is that not only it prolongs action but it attempts to maintain drug levels within the therapeutic window to avoid potentially hazardous peaks in drug concentration following ingestion or injection and to maximize therapeutic efficiency.

In addition to pills, capsules and injectable drug carriers that often have an additional release function , forms of controlled release medicines include gels, implants and devices e. Examples of cosmetics, personal care and food science applications often centre on odour or flavour release. The CRS is the worldwide society for delivery science and technologies.

CRS serves more than 1, members from more than 50 countries. Two-thirds of CRS membership is represented by industry and one-third represents academia and government. The earliest SR drugs is associated with a patent in by Israel Lipowski, who coated pellets which led to coating particles. Delivery is usually effected by dissolution, degradation or disintegration of an excipient in which the active compound is formulated.

Enteric coating and other encapsulation technologies can further modify release profiles. There is no industry standard for these abbreviations, and confusion and misreading have sometimes caused prescribing errors. For some drugs with multiple formulations, putting the meaning in parentheses is advisable. A few other abbreviations are similar to these in that they may serve as suffixes but refer to dose rather than release rate. They include ES and XS extra strength. Today, most time-release drugs are formulated so that the active ingredient is embedded in a matrix of insoluble substance s various: In some SR formulations, the drug dissolves into the matrix, and the matrix physically swells to form a gel, allowing the drug to exit through the gel's outer surface.

Micro-encapsulation is also regarded as a more complete technology to produce complex dissolution profiles. Through coating an active pharmaceutical ingredient around an inert core, and layering it with insoluble substances to form a microsphere one can obtain more consistent and replicable dissolution rates in a convenient format that can be mixed and matched with other instant release pharmaceutical ingredients in to any two piece gelatin capsule. The half-life of the drug refers to the drug's elimination from the bloodstream which can be caused by metabolism, urine, and other forms of excretion.

If the active compound has a long half-life over 6 hours , it is sustained on its own. If the active compound has a short half-life, it would require a large amount to maintain a prolonged effective dose. In this case, a broad therapeutic window is necessary to avoid toxicity; otherwise, the risk is unwarranted and another mode of administration would be recommended. The therapeutic index also factors whether a drug can be used as a time release drug. A drug with a thin therapeutic range, or small therapeutic index, will be determined unfit for a sustained release mechanism in partial fear of dose dumping which can prove fatal at the conditions mentioned.

Diffusion systems rate release is dependent on the rate at which the drug dissolves through a barrier which is usually a type of polymer. Diffusion systems can be broken into two subcategories, reservoir devices and matrix devices. Instead of diffusion, the drug release depends on the solubility and thickness of the coating.

Because of this mechanism, the dissolution will be the rate limiting factor here for drug release. Osmotic controlled-release oral delivery systems OROS have the form of a rigid tablet with a semi-permeable outer membrane and one or more small laser drilled holes in it.

As the tablet passes through the body , water is absorbed through the semipermeable membrane via osmosis , and the resulting osmotic pressure is used to push the active drug through the opening s in the tablet.

Osmotic release systems have a number of major advantages over other controlled-release mechanisms. They are significantly less affected by factors such as pH , food intake, GI motility , and differing intestinal environments. Using an osmotic pump to deliver drugs has additional inherent advantages regarding control over drug delivery rates.

This allows for much more precise drug delivery over an extended period of time, which results in much more predictable pharmacokinetics.

However, osmotic release systems are relatively complicated, somewhat difficult to manufacture, and may cause irritation or even blockage of the GI tract due to prolonged release of irritating drugs from the non-deformable tablet. In the ion-exchange method, the resins are cross-linked water-insoluble polymers that contain ionisable functional groups that form a repeating pattern of polymers, creating a polymer chain.

The area and length of the drug release and number of cross-link polymers dictate the rate at which the drug is released, determining the SR effect. A floating system is a system where it floats on gastric fluids due to low-density. The buoyancy will allow the system to float to the top of the stomach and release at a slower rate without worry of excreting it. This system requires there are enough gastric fluids present as well as food.

Bio-adhesive systems generally are meant to stick to mucus and can be favorable for mouth based interactions due to high mucus levels in the general area but not as simple for other areas.

Magnetic materials can be added to the drug so another magnet can hold it from outside the body to assist in holding the system in place. However, there is low patient compliance with this system. The matrix system is the mixture of materials with the drug, which will cause the drug to slow down. However, this system has several subcategories: Examples of stimuli that may be used to bring about release include pH, enzymes, light, magnetic fields, temperature, ultrasonics, osmosis and more recently electronic control of MEMS [21] and NEMS.

Some time release formulations do not work properly if split, such as controlled-release tablet coatings, while other formulations such as micro-encapsulation still work if the microcapsules inside are swallowed whole. Among the health information technology HIT that pharmacists use are medication safety tools to help manage this problem. For example, the ISMP "do not crush" list [25] can be entered into the system so that warning stickers can be printed at the point of dispensing, to be stuck on the pill bottle.

Pharmaceutical companies that do not supply a range of half-dose and quarter-dose versions of time-release tablets can make it difficult for patients to be slowly tapered off their drugs.

From Wikipedia, the free encyclopedia. This section does not cite any sources. Please help improve this section by adding citations to reliable sources. Unsourced material may be challenged and removed. February Learn how and when to remove this template message. Osmotic controlled-release oral delivery system. Drug Delivery and Targeting , p. Sustained Release Drug Delivery System. Indian Journal of Research in Pharmacy and Biotechnology.

Sustained Release Drug Delivery System: Release Drug Delivery System Potential. American Journal of PharmTech Research.

Drug delivery and targeting. Novel Oral Sustained Release Technology: European Journal of Pharmaceutics and Biopharmaceutics. Annals of the New York Academy of Sciences.

Current medical research and opinion. Drug development and industrial pharmacy. European journal of clinical pharmacology. International Journal of Research in Ayurveda and Pharmacy. Oral dosage forms that should not be crushed PDF.

Routes of administration , dosage forms. Mouthwash Toothpaste Ointment Oral spray. Smoking device Dry-powder inhaler DPI. Oxygen mask and Nasal cannula Oxygen concentrator Anaesthetic machine Relative analgesia machine. Intradermal Subcutaneous Transdermal implant. Intracavernous Intravitreal Intra-articular injection Transscleral. Category WikiProject Pharmacy portal.

Retrieved from " https: Dosage forms Routes of administration Drug delivery devices Pharmacokinetics. Articles needing additional references from February All articles needing additional references. Views Read Edit View history. This page was last edited on 3 February , at By using this site, you agree to the Terms of Use and Privacy Policy. Skin Intradermal Subcutaneous Transdermal implant.