Minimum wall-thickness for 3D printing tutorial

4 stars based on

33 reviews

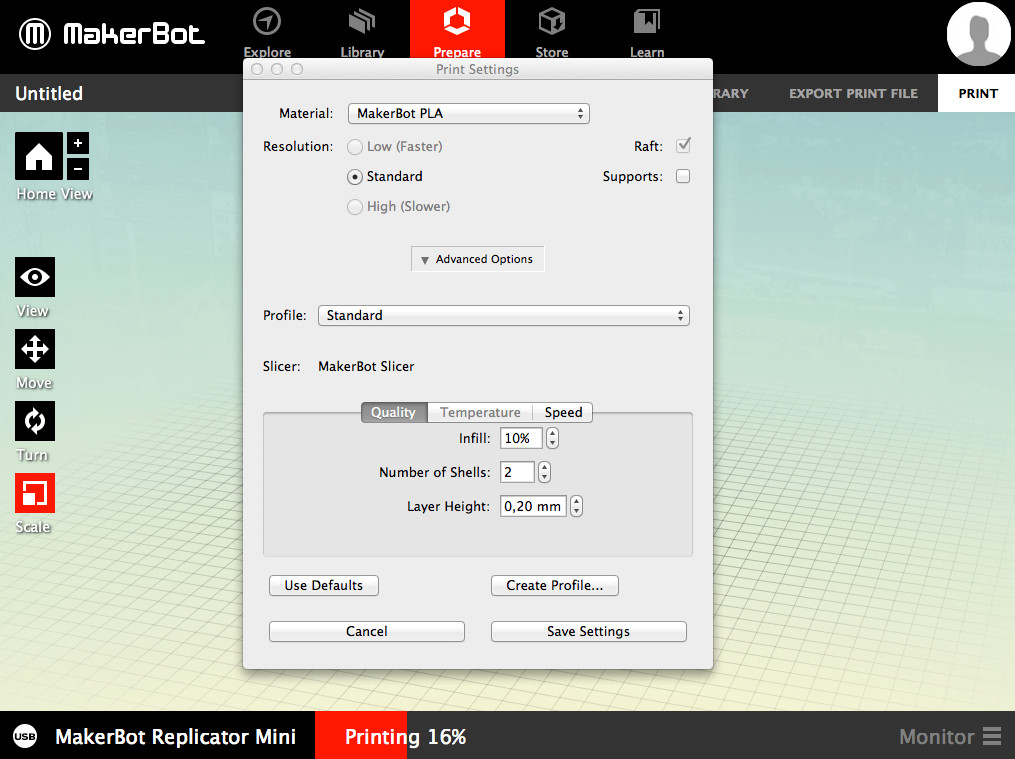

Standard Mode - a balance of high surface quality and quick print time. Quicker "sketch" mode - favors speed over surface quality. Great for multiple iterations. Fastest mode - uses the absolute minimum amount of internal structure. Ideal for large prints that don't need to be durable. You can makerbot replicator minimum wall thickness use modified Print Modes without saving the modifications.

To do this, simply click the desired Print Mode and make your modifications. The Print Settings panel is designed to help you pay attention to only the most important print settings. The number of outermost layers of the printer model. Increasing the number of shells creates thicker stronger walls, but slower prints.

Rafts help models adhere to the build surface and help create an even first layer. Adjusts the density of the infill on the inside of the print. If the top of the model is collapsing during a print or the model feels to brittle, increasing the makerbot replicator minimum wall thickness density may help. Increasing the density will increase print time. Adjusts the height of each printed layer. Increasing the layer height will result in faster print times but visibly thicker layer heights.

Makerbot replicator minimum wall thickness the speed of the gantry while the printer is not extruding. If the extruder is knocking over tall or unstable prints while moving between printed areas, slowing the travel speed may help.

Slowing the travel speed will increase print time. Minimum time for printing a layer. Layers that will print faster than the minimum will be slowed down. Minimum Layer Duration allows the plastic adequate time to cool before applying the next layer. The Filament Diameter is used to calculate the volume of plastic used in slicing filament. The Filament Diameter should be set to the diameter of filament being loaded into makerbot replicator minimum wall thickness extruder.

The diameter of all MakerBot Filaments is 1. Adjusts how much the filament is being pulled back into the extruder prior to travel moves. If the model is showing signs of stringing, increasing the retraction distance might help. Stringiness can also be caused by the filament being exposed to damp or humid conditions.

Adjusts the temperature of the extruder while filament is being extruded. Under Extrusion could be caused by the filament being too cold while extruding. Raising the temperature may makerbot replicator minimum wall thickness more filament to pass through. If the model starts to have stringing between sections, the temperature may be too high. Reducing the temperature may reduce stringing.

Adjusts the thickness of roof sections of the model. If there are visible gaps on the roof part of your model or you'd like a stronger print, increasing the roof thickness might help. Adjusts extruder movement speed while printing shells. Lowering the print speed on shells may increase smoothness of outward facing features and help smaller features and parts from falling over due to extruder movement.

Changes the location of the seam on the model. You may want to makerbot replicator minimum wall thickness the seam to preserve a uniform finish on certain faces of the model. Toggles random seam placement on and off. The seam is randomly placed throughout the print to prevent it from being noticeable. If a uniform seam is desired turn this feature on.

The direction of the seam faces can be chosen in the "Shell Starting Direction" setting. Adjusts extruder movement speed while printing infill.

Roof and floor appearance may be improved by decreasing infill print speed, print time will be increased. Linear is made up of parallel straight lines, perpendicular to the lines on the previous layer.

Linear infill is fast to print, and makes your toolpath simpler. Makerbot replicator minimum wall thickness infill is designed to be strong and to print quickly. Some infill patterns, like Catfill, Sharkfill and Moroccanstar, are just meant to be decorative and fun.

If your 3D printer receives too many commands too quickly, it could pause or freeze during a print.

To reduce the complexity of your toolpath, try decreasing the infill percentage, switching to a simpler infill pattern. For more information, see this article. If there are visible gaps in the floor part of your model or you'd like a stronger print, increasing the floor thickness might help. If the model is failing due to overhangs or layers that have no material to build on, turning on supports may help.

Supports snap off easily after printing. Adjusts the angle of a surface which determines when support is printed. If the model is drooping while printing certain sections because they are unsupported, decreasing the support angle will add support to parts printed at a shallower angle. Support to Model Spacing: The amount of area on the horizontal plane between support and model material.

Decrease the distance if there are very small parts of the model that need to be supported. If there is too much support in small areas, increasing the spacing may help. Adjusts the density of support material deposited. A higher density will make makerbot replicator minimum wall thickness removal more difficult. If the model is tall or some small parts of the model such as downward facing points, small towers, and tiny bridges are not being supported, change the support density.

Adjusts the maximum distance of a bridge before support material is printed underneath. If bridges are drooping, decreasing the maximum bridge length will add supports underneath.

Setting the distance to zero will add suports to all bridged areas. Adjusts the fan speed while printing the first model layer. If the first layer is not sticking well, turn down the fan speed. Another reason the raft may not be sticking well is the extruder is printing too far away.

Adjust the Z-Offset in printer utilities to change this. Adjusts the horizontal size of a raft around the radius of the model. If tall or top heavy models are falling over during printing, a larger raft may adhere makerbot replicator minimum wall thickness model to the build plate more successfully. A larger raft may also makerbot replicator minimum wall thickness the corners of a large print from curling up makerbot replicator minimum wall thickness lifting from the build plate. If the model is coming loose from the raft on the first layer, turning down the print speed may help.

Raft to Model Vertical Offset: Adjusts the margin between the raft and model during printing. If the model is sticking to makerbot replicator minimum wall thickness raft and hard to remove, increasing the raft to model vertical offset might help.

If the model is coming off the raft while printing, decreasing the model vertical offset might help. Register your device to ensure you get the right level of service and support. Activate Your Service Plan Register your device to ensure you get the right level of service and support.

I have a question about an existing order. I have a technical question about my device. For faster service, enter your order number found in your confirmation e-mail Makerbot replicator minimum wall thickness.